Glass fabrication details can make the difference between a glass piece that is easy to install or one that’s outright unusable — which can lead to costly delays.

Just like custom glass projects, no two commercial glass services companies are the same. All have different capabilities.

However, several glass design elements can impact all commercial glass fabricators and their ability to manufacture an end product that’s both functional and beautiful.

Making it Manufacturable: Design Considerations for Smooth Collaboration With Glass Fabricators

When designing a piece of custom glass, be mindful of these five elements that can make or quite literally break a project:

- Shape

- Size

- Holes

- Cutouts

- Edgework

Paying careful attention to these details during the design stage allows commercial glass companies to fabricate beautiful, custom-shaped pieces that meet your project’s demands.

(Need better communication with your commercial glass partner? Download this guide!)

1. Shape

Shapes — especially those that are non-traditional — can be tricky for commercial glass manufacturers. You can only cut glass once — that's why it's important to discuss glass shaping at the onset of a project. Intricate designs may exceed a glass manufacturer’s capabilities.

The best thing you can do to ensure the finished piece of shaped glass is exactly what you intended to order is to provide a quality template or pattern. A digital photo of where the glass will be installed is immensely helpful for irregularly shaped glass, such as pieces for slab furniture.

(Learn more about the different ways glass can be shaped! Download the guide.)

2. Size

Not all glass fabricators have the same equipment. That means each may have limitations on the size of pieces they can fabricate.

For instance, some large pieces cannot be fabricated as a single unit. A 20’ x 20’ wall mirror, for example, may need to be created in multiple pieces. Check with your manufacturer for any size limitations.

3. Holes

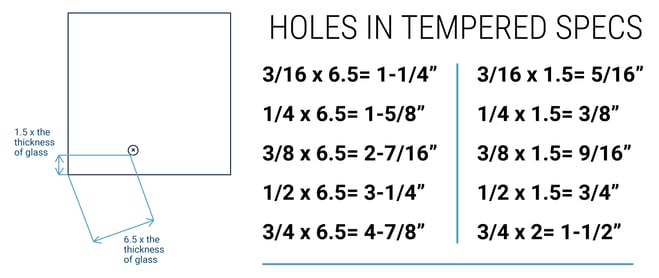

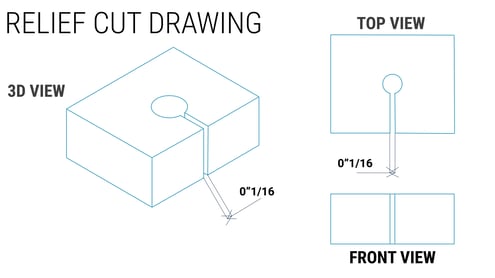

This is particularly important with glass tempering services. The minimum hole diameter needs to be equal to the glass pane’s thickness. The placement of a hole in a tempered glass piece can’t be too close to a corner or edge because it becomes nearly impossible to fabricate as specified. A slotted hole may be required when the hole is too close to the edge.

4. Cutouts

This applies mainly to single glass pieces with large cutouts, such as a bathroom mirror with a cutout for an inset medicine cabinet. Remember there are limits with the cutout/glass pane size proportions — the larger the cutout, the more risk there is for breakage.

5. Edgework

The thickness of your glass impacts the style of edgework you can use. Again, there are manufacturer limitations.

For example, at New Angle Beveling, an ogee edge is only available on ½″ and ¾″ thick glass, while a bullnose edge is ½”. We can only complete the triple pencil edge (waterfall) on ¾” glass.

Communicating Designs to Commercial Glass Fabricators

Designing a glass piece that meets a custom fabricated glass service company’s capabilities is only half of creating a manufacturable project.

The other: communicating precisely what you expect of the finished product to glass fabricators.

Tell your commercial glass manufacturer exactly what you’ll be using the glass for and discuss all of your specifications upfront, even down to details such as tolerances. This ensures you are both on the same page. If you can help the manufacturer see your vision — even by providing a rough sketch of the desired finished product — the likelihood of getting it right the first time increases drastically.

(Learn more about our services and capabilities. Click on the button below!)

By providing sufficient information and guidance on your project up-front, you reduce the need for back-and-forth telephone calls during production. This saves time — and labor costs — on everyone’s part and ensures you get the right product on time the first time.

Ask questions and be open to recommendations. If you don’t understand some terminology, just ask your glass fabrication partner and they’ll be happy to clarify. This makes the entire quoting, logistics, and manufacturing processes much easier.

With in-depth information and excellent communication up-front, a skilled glass vendor using modern technology and state-of-the-art machinery can produce custom, high-quality pieces that make commercial glass installation a breeze.

Designing a custom glass project?

We’d be happy to help you. Use the button below and we’ll be in touch soon.

(Editor's note: This article was originally published in August 2020 and was recently updated).