Details matter when fabricating a piece of commercial glass.

Though tolerances are among the littlest elements of glass fabrication, they can significantly impact the quality of a finished piece.

Without discussing glass fabrication tolerances -- especially during the quoting stage of a project -- you risk receiving a glass piece that doesn't meet your specifications, on top of wasted time and effort, and increased costs.

Use this guide to understand how effectively communicate your project’s glass fabrication tolerances to a commercial glass company.

What Are Tolerances in Commercial Glass Manufacturing?

Tolerances are the minimum and maximum variations from a piece’s original measurements before it becomes unusable. In other words, tolerances are the wiggle room a glass piece has so that it can still fit and function as intended.

As there’s rarely a 100% perfect pane of glass, commercial glass manufacturers often need to make slight adjustments to a piece to remove imperfections.

For instance, a pane may have a surface blemish or chip along its edge. Working within manufacturing tolerances, a glass fabricator can remove the tiny defect with additional cutting or grinding and not jeopardize the piece’s ability to fit where it needs to.

Resource: Tolerances are just one thing your commercial glass manufacturer should know about your project. Download our guide to learn how to best partner with a commercial glass company:

What to Tell a Commercial Glass Manufacturer About Your Project’s Tolerances

When partnering with a commercial glass manufacturer for standard glass fabrication, there are several pieces of information you should always provide:

- Dimensions: Length, width, and thickness.

- Edgework: Thickness, piece size, width-to-height ratio.

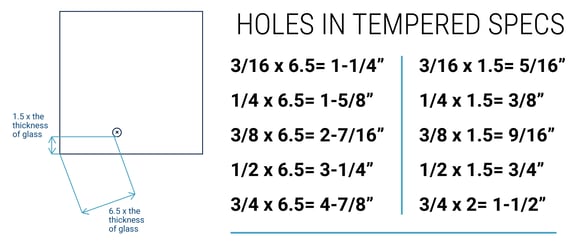

- Holes and notches: Hole or notch location, placement tolerances based on the width of glass, radius, diameter, chip tolerance.

- Tempering: Thickness, size, diagonal dimension, bow and warp allowances.

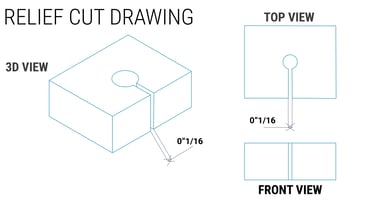

Projects that need tempering near holes may require a relief cut. Relief cuts are only necessary in tempered glass applications where the holes are too close for our specs and cannot be moved.

It’s important to remember that different commercial glass manufacturers have varying tolerance capabilities. At New Angle Beveling, we always strive to produce exactly what the customers wants, and we keep tolerances to a minimum. This tolerance chart shows what our capabilities are:

|

Dimensional Tolerance |

+ |

- |

|

1/4" |

1/32" |

1/16" |

|

3/8" |

1/32" |

5/23" |

|

1/2" |

1/32" |

5/23 |

|

3/4" |

1/8" |

1/4" |

Tolerance Information for Specialty Custom Fabricated Glass

Intricately shaped pieces, such as patterned and shaped glass, may have tight or non-existent tolerances. This information is critical to discuss with a glass manufacturer during the quoting process. Creating glass pieces with little room for size deviation requires additional planning and labor, impacting final production costs.

Quality Renderings = Accurate Tolerances

Renderings can be a glass manufacturer’s best friend in both quoting and completing a project.

When drawings are required to highlight specific fabrication details, submit clear and detailed sketches that include all required tolerance information. This knowledge is especially critical when projects have tight or no tolerances.

Label every drawing submitted to ensure the finished piece you receive is the same as the one you intended to order.

For larger custom glass pieces or those requiring a template, it’s best to provide a digital rendering, though traditional renderings are acceptable.

Large patterns submitted on taped-together paper leave room for error -- if a piece comes off or moves slightly, a glass manufacturer will likely struggle to put it back together exactly as before.

When it is time to finalize an order, submit the most recent version of your project’s rendering. That ensures a glass manufacturer is working with the most up-to-date information.

Communicating Glass Tolerances From the Beginning

Communicating with your glass manufacturer is key to getting glass fabrication tolerances right the first time.

The best time to discuss tolerances is during the quoting process. Without the necessary tolerance information upfront, a glass beveling company may not be able to provide you with an accurate quote or finished piece.

Ready to get started on your custom glass project?

Use the button below, and we’ll be in touch soon.

(Editor's note: This article was originally posted in July 2020 and was recently updated).