There are multiple ways to get started on your next project with your commercial glass company. But there can be a simplified way to streamline your process to get clear results.

Remember: working with a commercial glass company on a project represents a partnership of sorts. The key to a successful partnership?

Communication.

Before starting a commercial glass project with a glass manufacturer, several pieces of information should be shared up-front, no question.

Providing these nine details ensures your job is completed with minimal hassle, little deviation from a quoted price, and no delays.

The 9 Project ‘Must Knows’ for Your Commercial Glass Company

While no two commercial glass projects are identical, the information your glass vendor needs about your project is the same as it is for any other.

When working with a commercial glass company, here are nine things they’ll need to know before starting your project:

- Project scope

- Budget

- Deadline

- Dimensions

- Cutout/Hole information for hardware requirements

- Tolerances

- Packaging

- Delivery location

- Shop limitations

1. Project Scope

First and foremost, your commercial glass fabricator will need to know what exactly you’re working on.

For every project, there’s an ideal glass type. Knowing exactly what your project is will allow a glass manufacturer to provide its expertise in selecting the correct glass and making sure it meets the demands of its intended use.

2. Budget

The amount you’re able to spend isn’t something to hide for fear of unnecessary upcharges or add-ons.

A reputable commercial glass company is there to help you make the best, cost-effective decisions possible. Sharing your budget helps a glass company provide you with the best information and products possible.

Being up-front with your budget also invites an extra layer of review by an expert -- perhaps your budget is too low for the type of glass your project requires.

3. Deadline

Your project’s deadline impacts more than just when you intend to complete a job. It also extends to the third-party elements of finishing a job, such as specialized trades workers or commercial glass companies.

The commercial glass for your project may require more time to manufacture depending on its type or the size of the order. A glass manufacturer may need to make special arrangements to meet your timetable.

4. Dimensions

In actually fabricating your glass, the exact dimensions and shape of the glass are critical.

Without precise measurements, you’re all but guaranteeing that you’ll receive wrong sized or misshapen custom fabricated glass through no fault of the manufacturer.

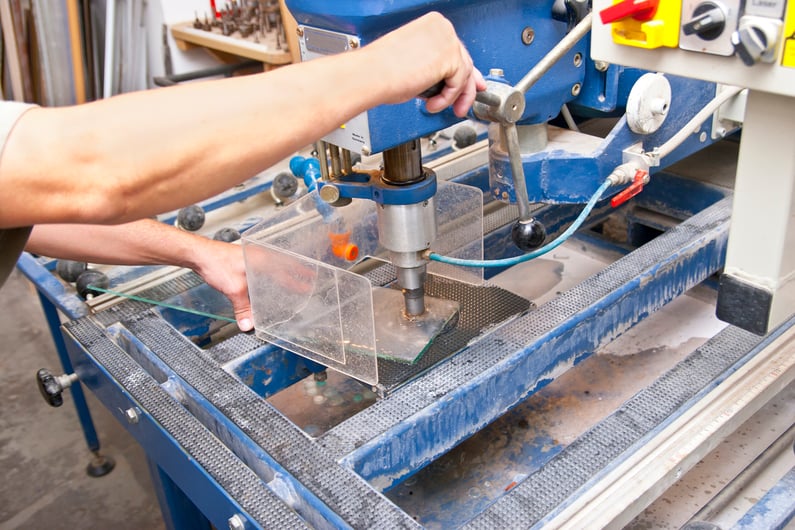

5. Cutout/Hole Information for Hardware Requirements

Along with exact dimensions, commercial glass companies need to know any hardware requirements for your glass -- particularly when seeking a quote. This is especially important with tempered glass, as fabrication needs to happen well before a pane is heat treated.

Sometimes, custom glass sheets need holes or notches cut in to accommodate the hardware. These elements impact the glass manufacturing process. Knowing hardware requirements is especially important if specialized cuts are needed.

6. Tolerances

Getting the wrong-sized piece, even by a fraction of an inch, can jeopardize a piece of glass fitting exactly where it needs to be. Providing tolerance information ensures you’ll still receive a usable piece of glass or custom glass sheet even if it needs some additional work to clean up imperfections.

Resource: Click the button below to learn more about tolerances:

7. Packaging

While a commercial glass manufacturer knows how to package glass so that it’s protected during shipping, you may have special packaging requirements.

Your glass might be moved again or not opened immediately after delivery. In these cases, you’ll need a few extra layers of protection until you’re ready to install it.

8. Delivery Location

The glass you ordered may not be headed directly to your shop.

As obvious as it sounds, commercial glass manufacturers need to know where the finished product is headed. This is especially important for deliveries going to bigger job sites where it’s easy to get lost. Imagine showing up at a hotel construction project with glass for dozens of custom shower enclosures and not knowing where to leave the shipment. If you have any particular needs for how your glass is shipped, mention them well ahead of time so your order arrives safely.

9. Glass Shop Limitations

If the glass you’ve ordered is headed to your shop, are you prepared to receive it?

Do you have enough people available to help lift it? Will it fit through the doors to get inside? There’s nothing worse for a delivery person from a wall mirror supplier than not being able to get the order through the front door.

A Few ‘Must Ask’ Questions for Your Commercial Glass FabricatorHow do you handle project timelines and deadlines?Ask about their process for scheduling and managing timelines. Make sure they address how they handle potential delays and how they get their project back on track. Can you provide examples of similar projects you have completed?Ask about previous projects they have completed and their strategy in completing them. This can help you asses their experience and expertise in handling specific requirements. What are your quality assurance processes?Ask about their quality control measures throughout each project phase. Understanding their standards and testing procedures is important for making sure the finished product(s) meets your high standards. How do you manage communication and updates during the project?Determine how they communicate, whether it’s via phone or email – or even in person. Effective communication is key to resolving issues smoothly and making sure the project aligns with your goals |

A Clear Conclusion for Your Commercial Glass Project

With the right -- and necessary -- information, your partnership with a commercial glass company can easily equal success. You’ll be able to complete your project with no unnecessary delays or added expense.

Have a Commercial Glass Project?

Request a quote today!

(This article was published in August 2020, and was recently updated)