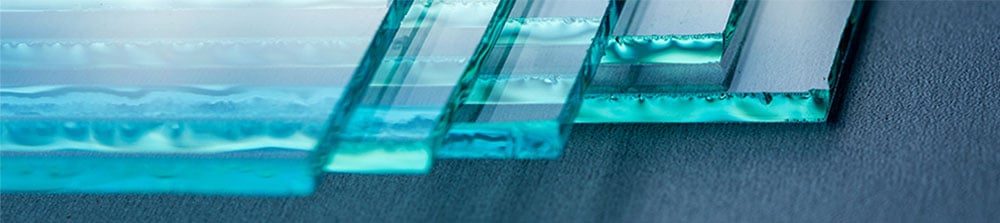

As those in the commercial and residential construction industry know, tempered glass is nearly 5x stronger than regular annealed glass. Tempering means heating the glass to extreme temperatures and rapidly putting it through a high-pressure cooling process.

This procedure puts stress on the glass, which in turn produces tension that begins in the center of the piece and spreads out. The tension is then compressed on the outer edges, which gives the glass sheet its strength.

How is glass tempered? Here's a “behind the scenes” look at the five-step glass tempering process.

The Glass Tempering Process

After a piece of glass has been fabricated, it is ready to be tempered.

The following steps make up the glass tempering process:

- Cutting

- Inspection

- Removal of contaminants and rough edges

- Extreme heating

- Rapid cooling

Here is a closer look at each step and its unique purpose:

1. Glass is cut into the desired shape

The first step is to cut the glass into the desired shape. Fabrication, such as edging or etching, must be completed before tempering, or the integrity of the final process could be compromised.

2. The glass is inspected

Tempering is an extreme temperature process, so the glass sheet needs to be free of any defects which could weaken it structurally.

A trained inspector carefully inspects the glass for any bubbles or cracks that may prevent the glass from being tempered.

3. Contaminants and rough edges are removed

Sandpaper or a gentle abrasive removes any sharp edges from the glass. There is a variety of grinding and fabrication work that can take place during this step, including selecting from a variety of edgework styles.

The piece is then thoroughly washed to remove any remaining grains of glass produced during this process and any other specks of dirt that could weaken the final temper.

4. The glass is heated to an extreme temperature

Glass is fed into a tempering oven in batches or as part of a continuous feed process. The industry standard temperature for a tempering over is 620° Celsius, or 1,148° Fahrenheit.

5. Rapid cooling, or quenching

The glass undergoes a rapid-fire, high-pressure cooling procedure. This process lasts just seconds, as air blasts from a precisely-placed array of nozzles quickly cool the outer surfaces of the glass.

As the center cools, it tries to pull back, which leaves it in tension while the outer surface is in compression. This dichotomy is what gives tempered glass its impressive strength.

NOTE: Another possible process is chemical tempering, but it is more expensive than the traditional heating and cooling procedure. Here, various chemicals are applied to the glass to create an exchange of ions on its surface, which creates the needed compression. New Angle Beveling does not offer this service.

Resource: Want to know what else a glass manufacturer can do? Download our Services and Capabilities guide:

The Benefits of Tempering Glass

After tempering, the glass receives a final quality inspection before delivery to the customer. Tempered glass has many benefits, including:

- Strength: The process makes tempered glass four to five times stronger than non-tempered pieces of glass because glass in tension breaks about five times easier than it does in compression.

- Flexibility: Tempered glass can be cut into several shapes, sizes, and patterns.

- Beauty: Additional beauty can be added to tempered glass through beveling, polishing, or v-grooving.

- Safety: If it should somehow manage to shatter, tempered glass uniquely breaks into small, less-jagged pieces instead of dangerous glass shards.

- Applications: The non-shatter element makes tempered glass perfect for applications with high use, where a traditional break could cause serious injury. Applications include shower enclosures, doors, walls, railings, outdoor furniture, indoor furniture, display cases, office walls, and lighting fixtures.

A skilled glass vendor using modern technology and state-of-the-art machinery can produce custom, high-quality tempered glass pieces that are perfect for many applications.

Want to Save This Information for Later? Download our Guide!

Download our Glass Tempering 101 Infographic Guide below!

(Editor's note: This article was originally published in December 2019 and was recently updated.)